All Valence locations are considered suppliers to Essential Critical Infrastructure and remain open for business. Please know that we at Valence Surface Technologies are doing everything in our power to mitigate the transmission and spread of the COVID-19 virus. For more information regarding our COVID-19 Response – Click here for more information.

-

VALENCE SURFACE TECHNOLOGIES

Valence Surface Technologies is pleased to announce the acquisition of Fountain Plating Company, Inc.

VISIT VALENCE WEBSITE -

A COST-EFFECTIVE RESOURCE

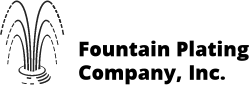

Fountain’s ability to provide a wide range of services within our 92,000 square foot facility streamlines the production of parts that require complex or multiple stages of processing and finishing. This one-stop-shop philosophy saves our customers both time and money.

PROCESSES & SERVICES -

APPROVED FOR THE TOUGHEST JOBS

Fountain Plating Company, Inc. completes critical assignments from clients who insist on the most demanding process and quality control standards.

CUSTOMERS -

ADVANCED PERFORMANCE SOLUTIONS

Fountain Plating’s 75 years of experience in metal finishing, its confident attitude and superior quality are well known throughout the industry.

ABOUT US -

SUCCESS IS THE ONLY OPTION

Every industry requires parts that deliver performance without compromise. Ensure success. Turn to Fountain Plating for the solutions that perform.

APPROVALS -

ABRASIVE BLASTING

Fountain Plating has the ability to abrasive blast large parts up to 144 inches in diameter with a wide variety of abrasives.

LEARN MORE -

ELECTROLESS NICKEL BORON

Fountain Plating has developed its own, unique electroless nickel boron process which produces a very hard, wear resistant coating suitable for replacement of hard chrome in many applications. This finish is available in standard or in a non-reflective black color.

LEARN MORE -

PHOSPHORIC ACID ANODIZE (PAA)

Fountain Plating has the ability to clean, PAA and paint/prime large parts up to 144 inches in diameter.

LEARN MORE -

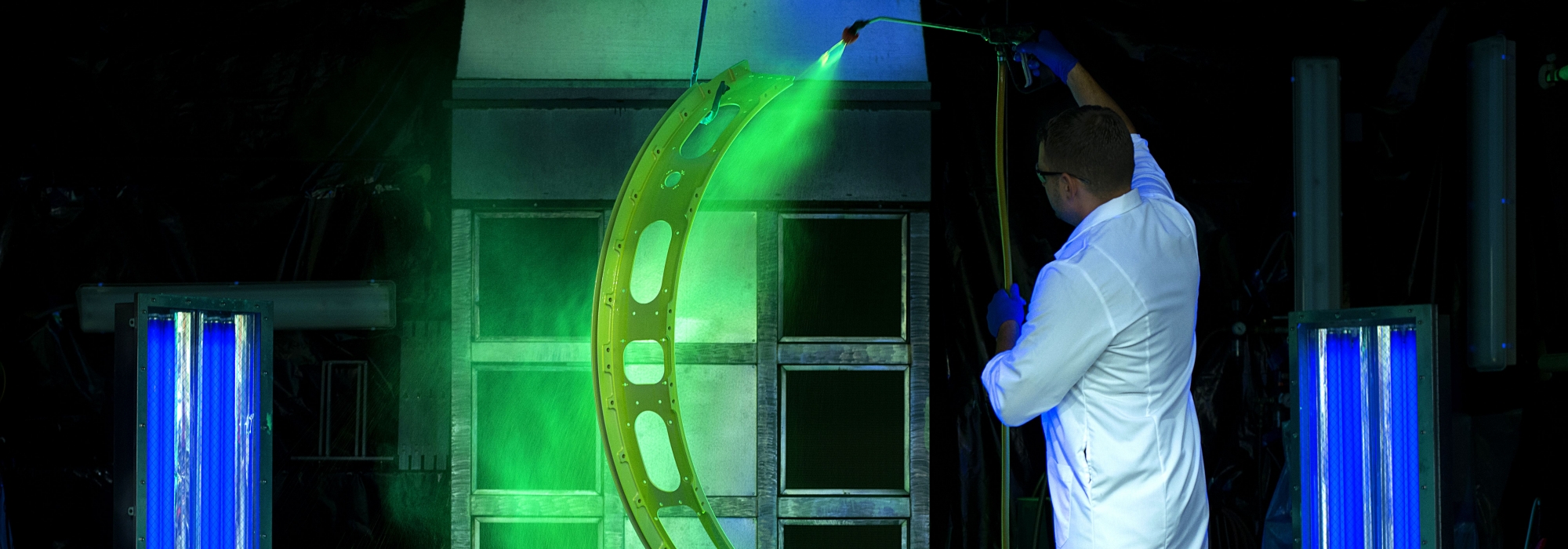

FLUORESCENT PENETRANT INSPECTION (FPI)

Fountain Plating has the ability to perform FPI on large parts up to 16 feet in length.

LEARN MORE